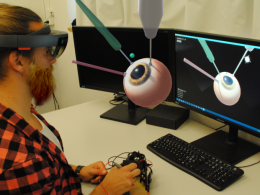

AtlasVR has joined forces with suissetec and is influencing the plumbing apprenticeship. The basic training is now being expanded with a VR module. The apprentices now learn and train the sealing of flat roofs virtually.

ETH spin-off AtlasVR offers virtual reality (VR) training solutions for industry that allow employees to train themselves independently and efficiently. A major advantage of software-based VR training is that industry saves a lot of raw material that would otherwise be wasted. Another advantage is seen in the reduced travel of trainers.

At suissetec, around 300 apprentices per year learn how to seal flat roofs with our virtual technology, which was previously only learned with a gas flame and bitumen. This saves the procurement and disposal of bitumen as well as large quantities of propane gas. Furthermore, our technique is very safe, the risk of injury is zero. For these reasons, VR training is a revolutionary improvement over traditional training.

Various industrial sectors

AtlasVR technology is designed to optimise training efficiency and development in the mechanical, electrical and metal (MEM) and building services industries. The use of this VR training solution enables companies in these industries to close skills gaps and shortages in a cost-, time- and resource-efficient way. The virtual reality-based software solution is accessible to a wide range of B2B customers. As the solution can be tailored to the needs of any application in the MEM and building services industry, the software can be used wherever goods are produced, repaired or maintained.

Easy entry into technical fields

In an interview with Bildung-Schweiz, Christian Hirt, AtlasVR co-founder, explains what their next goals are: "In the next few years, we want to reach as many learners, students and apprentices as possible to help them enter technical fields by also expanding our training solutions to additional industries. At the same time, we place great emphasis on sustainability and will continue to strive to reduce our ecological footprint through sensible use of VR so that costs for raw materials and travel can be minimised."

Source: Swiss Education / ETH